solidworks simulation is a first pass stress analysis tool for SolidWorks users. It helps you judge whether your part will withstand the loading it will receive under real-world conditions according to factor of safety.

Overview

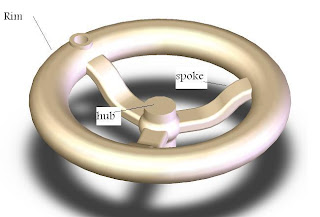

COSMOSXpress uses a wizard to provide an easy to use, step by-step method of performing design analysis. The wizard requires several pieces of information in order to analyze the part: materials, restraints and loads. This information represents the part as it is used. For example, consider whathappens when you turn the handwheel. The hub is attached to something that resists turning. This is represented by a restraint - the hub is restrained so it doesn’t move. A force is applied to the hole in the rim as you attempt to turn the handwheel. This is a load. What happens to the spokes? Do they bend? Will they break? This depends on the strength of the material the hand wheel is made of, the physical size and shape of the spokes, and the size of the load.

Mesh

In order to analyze the model, COSMOSXpress automatically meshes the model, breaking it up into smaller, easier-to-analyze pieces. These pieces are called elements.

Although you never see the elements, you can set the coarseness of the mesh prior to the analysis.

Results

The analysis produces results in the forms of Factor of Safety, Stress Distribution and Deformed Shape.

Using the Wizard

The design analysis wizard walks you through the steps of analysis, from Options to Results. The steps are:

Overview

COSMOSXpress uses a wizard to provide an easy to use, step by-step method of performing design analysis. The wizard requires several pieces of information in order to analyze the part: materials, restraints and loads. This information represents the part as it is used. For example, consider whathappens when you turn the handwheel. The hub is attached to something that resists turning. This is represented by a restraint - the hub is restrained so it doesn’t move. A force is applied to the hole in the rim as you attempt to turn the handwheel. This is a load. What happens to the spokes? Do they bend? Will they break? This depends on the strength of the material the hand wheel is made of, the physical size and shape of the spokes, and the size of the load.

Mesh

In order to analyze the model, COSMOSXpress automatically meshes the model, breaking it up into smaller, easier-to-analyze pieces. These pieces are called elements.

Although you never see the elements, you can set the coarseness of the mesh prior to the analysis.

Results

The analysis produces results in the forms of Factor of Safety, Stress Distribution and Deformed Shape.

Using the Wizard

The design analysis wizard walks you through the steps of analysis, from Options to Results. The steps are:

- Options

- Material

- Restraint

- Load

- Analyze

- Results